Advancements in Subsea Production Systems for Oil and Gas

Advancements in Subsea Production Systems for Oil and Gas

Blog Article

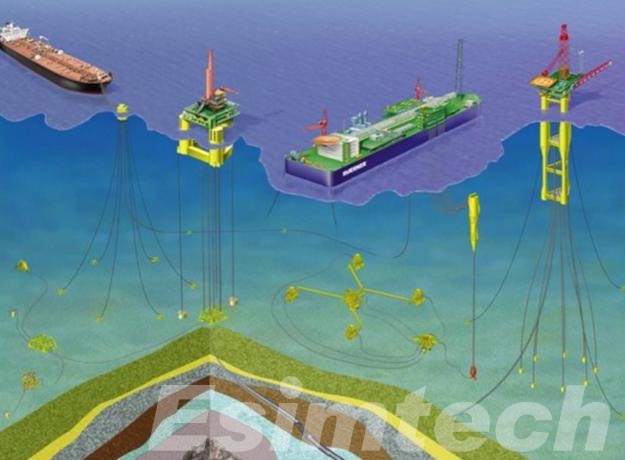

With the continuous rise in demand for oil and gas resources, the pace of offshore development is accelerating, with the deep sea becoming a focal point. The subsea oil production system is a crucial technology for extracting hydrocarbons from beneath the seafloor, contrasting with surface mining methods like fixed platforms and floating production facilities. These systems arrange production manifolds underwater and incorporate various multiphase pumps, separators, and communication control facilities. Submarine pipelines connect the extracted liquids back to nearby underwater or surface support facilities for processing. Throughout the production process, monitoring and control are managed from surface facilities via underwater umbilical cables.

Advantages of Subsea Production Systems

The subsea production system has emerged as a vital model for future oil and gas development due to its numerous advantages:

- Strong Adaptability: These systems can function at varying water depths and withstand harsh underwater conditions.

- Small Footprint: By installing many devices on the seabed, subsea systems significantly reduce the load and footprint on surface platforms.

- Reduced Reliance on Surface Facilities: They minimize dependence on surface and onshore treatment facilities, overcoming limitations of long-distance transportation.

- Improved Recovery Rates: Subsea systems enhance the recovery rate and speed of oil and gas field development.

- High Efficiency and Safety: They offer a high level of operational efficiency, safety, and economic viability.

Current State of Subsea Production Technology

Countries like Norway, the United States, and Brazil have mastered the key technologies behind subsea production systems. In contrast, China's offshore development has started relatively late, primarily focusing on shallow waters within 300 meters. However, deep-sea technology in China is progressing, with an emphasis on mastering subsea production systems to pave the way for future technological breakthroughs.

Traditional Underwater Production System

The traditional underwater production system includes essential components such as the underwater wellhead and Christmas tree system. The Christmas tree serves as a control channel and monitoring equipment for underwater production. It collects extracted materials from multiple oil wells through electric submersible pumps and pipelines, transporting them directly to the surface without any treatment.

The underwater wellhead consists of casings and casing heads, supporting the production tree and facilitating fluid flow. The Christmas tree includes various components such as the body, connectors, valves, and control systems, and is more complex than onshore versions. There are two types of Christmas trees: vertical and horizontal. The primary distinction lies in the orientation of the valve group relative to the production tubing.

Choosing the Right Christmas Tree

When selecting a Christmas tree, various factors must be considered, including the characteristics of the oil and gas field, underwater environment, and operational habits. Key design and manufacturing considerations include:

- Pressure Bearing

- Sealing and Insulation

- Thermal Insulation

The choice between vertical and horizontal Christmas trees often depends on operational requirements and maintenance considerations, with horizontal trees being favored for larger diameters and easier access.

As offshore oil and gas development continues to evolve, subsea production systems play a pivotal role in enhancing extraction efficiency and safety. With ongoing advancements in technology and design, these systems are set to revolutionize the future of oil and gas production.

Report this page